🛠️ Getting Started

How it Works

The Assembly app allows you to build finished goods from component SKUs defined in a Bill of Materials (BOM), using real-time inventory data from your Linnworks account.

This tool provides full visibility into:

- ✅ Which components are available and which are limiting production

- ✅ How many units can be built right now, per location

- ✅ The flexibility to adjust BOMs before committing to a build

Once assembled, the app automatically:

- 📉 Deducts inventory for each used component

- 📈 Increases inventory for the finished product

- 🔄 Syncs all changes directly with Linnworks

No manual adjustments. No surprises.

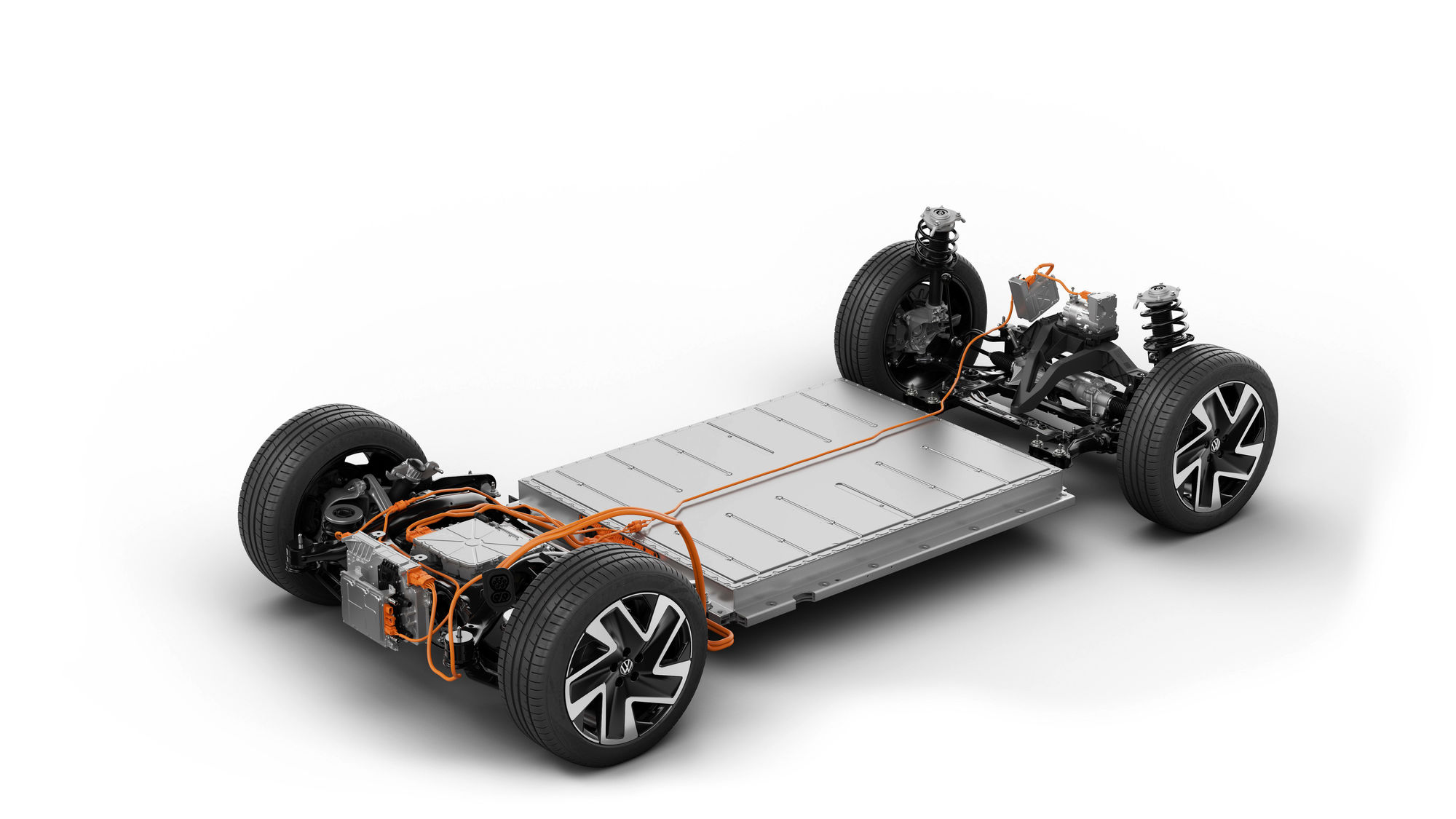

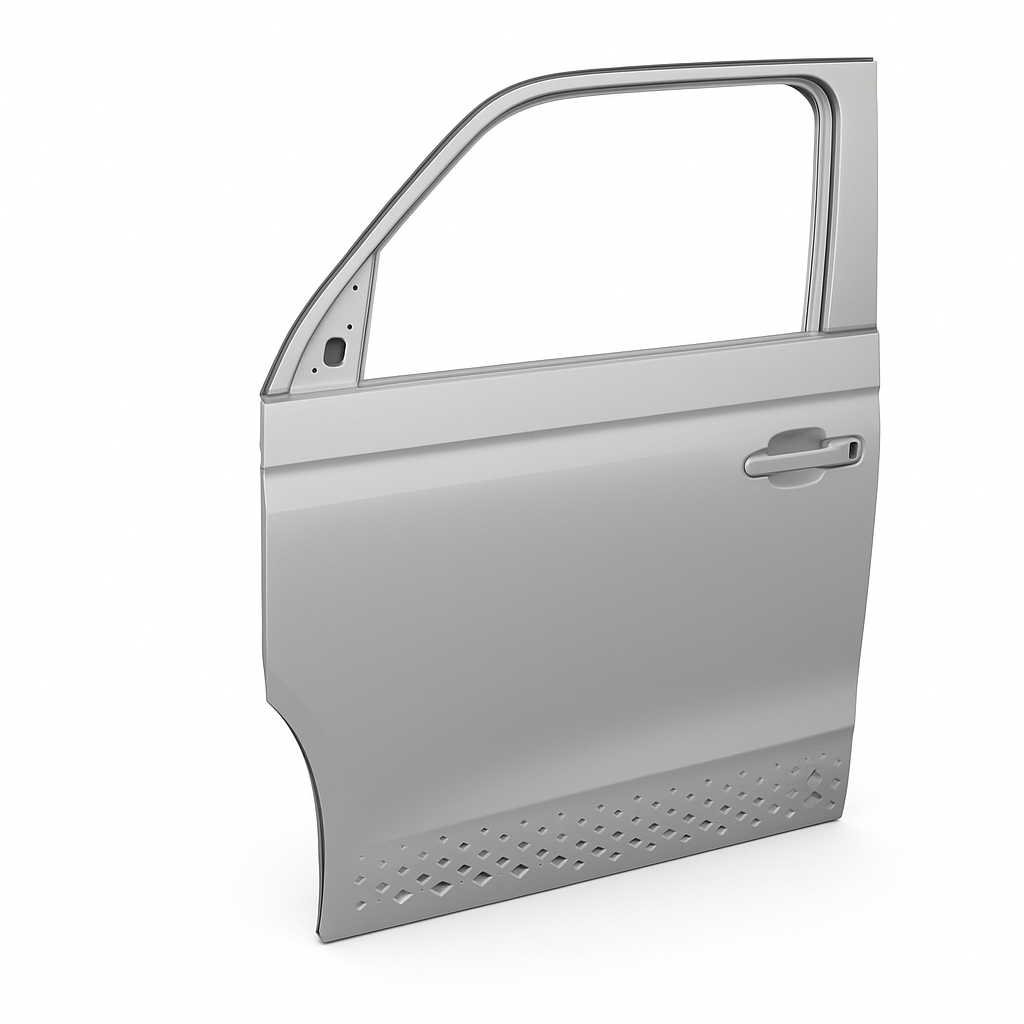

🏗️ Example: Assembling an Electric Van

To help visualize what this app actually does, here’s a simple example BOM (Bill of Materials) to assemble one electric van.

The Assembly app uses your current inventory to determine how many complete vans you can build — and highlights which parts are limiting production.

🧾 Bill of Materials (1x Electric Van)

| Image | Component | Qty Required |

|---|---|---|

| Body Shell | 1 |

| EV Chassis | 1 |

| Battery Pack | 1 |

| Side Door | 2 |

| Wheels | 4 |

| Paint Unit | 1 |

The app checks your inventory for these components and calculates how many complete vans you can build — instantly.

The Assembly app will:

- Check current inventory levels for each component

- Calculate how many complete vans you can assemble

- Highlight if you’re short on any part (e.g. only 3 wheels available = build limit 0)

- Let you build what you can, adjust the BOM if needed, and optionally save your new BOM

- Automatically update stock levels in Linnworks

Think of it like a digital assembly line — but stock-aware and fully automated.

Open the Application

- In Linnworks, go to the left-hand side menu

- Navigate to Apps → LinnFactory → Assembly

- The Product Assembly interface will open in a new tab

Search for SKU

- Use the search bar (top right) to find the finished product SKU you want to assemble

- Start typing and the app will return matching SKUs from your inventory

- Select the product to load its image, BOM, and stock data

Select Inventory Location

Use the dropdown next to the search bar to choose the inventory location.

- All component availability and stock updates will be based on this selection

- The Max Build Qty. will recalculate dynamically based on the selected location

Note: All calculations, warnings, and assemblies are location-specific.

Review BOM & Stock Data

When a product is selected, the app displays:

- Current stock of the finished product

- Max build quantity (based on lowest available component)

- A table of components with:

- SKU

- Name

- Current availability

- Part count

- Edit/remove actions

⚠️ Components that limit production appear with a red background.

Edit the BOM

Adjust Quantities

- Use the + / – controls to change part count per unit

- The Max Build Qty. updates in real time

Add or Remove Components

- Click “Add Part” to add a new component

- Use the trash icon to remove any item from the temporary BOM

Changes are temporary unless saved.

Save or Reset Changes

When the BOM is edited, you’ll be prompted to:

- Save – writes changes to Linnworks Extended Properties, making them permanent

- Reset – discards changes and reloads the original BOM

If you navigate away without saving, changes will be lost.

Assemble Parts

- Set the quantity to build in the bottom right panel

- The app shows the maximum allowed based on stock

- Click “Assemble parts” to complete the process

What happens:

- Stock is deducted for each component

- Finished product inventory increases

- Inventory is synced to Linnworks immediately

Summary

LinnFactory Assembly gives you:

- A faster, more visual way to plan and produce products

- Real-time constraint visibility

- Flexible BOM editing with optional save

- Instant inventory sync